Modbus RTU Fuji Alpha 5 with Omron NB10

Application

- Control Fuji

Alpha 5Servo Motor with OmronNB10HMI. Servo OnandRunwould be controlled from PLC with Digital IO.- Setting of Speed and Monitoring from HMI

- PLC outputs are

NPN.

Electrical Wiring

Three types of of Wirings

- High Voltage wiring for

Servo Drive, Servo drive to motor with prefabricated Cables from Fuji. - Digital control Wiring between Drive

IO ConnectorandPLC. - Low voltage wiring for

HMI - Communication Cable between

Servo DriveandHMI - Communication Cable between

PC LoaderandDrive

Drive and Motor Wiring

- Connect

220V ACtoL1andL2on the Drive. - Connect

U, V, Won the drive to Motor Power Connector. Encodercable from DriveCN2port to Motor Encoder.

Control Wiring

Fuji Alpha 5 has IO connector on CN1 port.

CN2 IO Cable

| Pin No | Terminal symbol | COLOUR |

|---|---|---|

| 1 | COM IN | Red |

| 2 | CONT1 | Brown |

| 3 | CONT2 | Green |

| 4 | CONT3 | Violet |

| 7 | CA | Blue |

| 8 | *CA | Black |

| 14 | COM OUT | White |

| 15 | OUT1 | Gray |

| 19 | PPI | Pink |

| 6 | M5 | Yellow |

Follow the bellow wiring

- Connect

RedWireCOM INto24 VDC - Connect

BrownWireCONT1toPLC OutputforServo ON - Connect

GreenWireCONT2toPLC OutputforServo Run

Communication Wiring Drive to HMI

Fuji Alpha 5 has RJ45 with port CN 3A (IN) to NB HMI COM2 DB9 Connector

RJ45 Connector with Cat 6 cable on Drive Side

| Pin No | Cable Color |

|---|---|

| 3 | White/Orange |

| 4 | Brown |

| 5 | White/Brown |

| 6 | Orange |

9 Pin Connector on HMI Side

| Pin No | Cable Color |

|---|---|

| 6 | White/Orange, White/Brown |

| 8 | Brown, Orange |

Communication Wiring Drive to Drive

Fuji Alpha 5 has RJ45 with port CN 3B (OUT) to Fuji Alpha 5 has RJ45 with port CN 3A (IN)

| Pin No | CN 3B (OUT) | CN 3A (IN) |

|---|---|---|

| 1 | Blue | Blue |

| 2 | White/Blue | White/Blue |

| 3 | White/Orange | White/Orange |

| 4 | Brown | Brown |

| 5 | White/Brown | White/Brown |

| 6 | Orange | Orange |

| 7 | White/Green | White/Green |

| 8 | Green | Green |

Communication Wiring Drive to PC Loader

Connect Programming PC with USB to RS422/485 Converter

| Pin No | CN 3A (IN) |

|---|---|

| 3 | T/R + |

| 4 | T/R - |

| 5 | T/R + |

| 6 | T/R - |

Parameters

- Parameter

PA3:01to1for SettingCONT1Signal asServo ON. - Parameter

PA3:02to2for SettingCONT2Signal asServo RuninForwarddirection. - Parameter

PA3:02to3for SettingCONT2Signal asServo RuninReversedirection.

To change the direction without modifying CONT2 parameter, Set PA3:02 to 2 and set PA1:04 to 0 for CCW or 1 for CW.

HMI Program

- Create a New project in

NB-Designerand Select correct HMI Model fromPTinProject Library Window. - In

PLCtab ofProject Library Window, SelectModbus RTU Extended. - Set Station Number same as Node address of the

Fuji Drive - From

Connectorstab, selectSerial Portand connect drive and HMI.

Speed Change

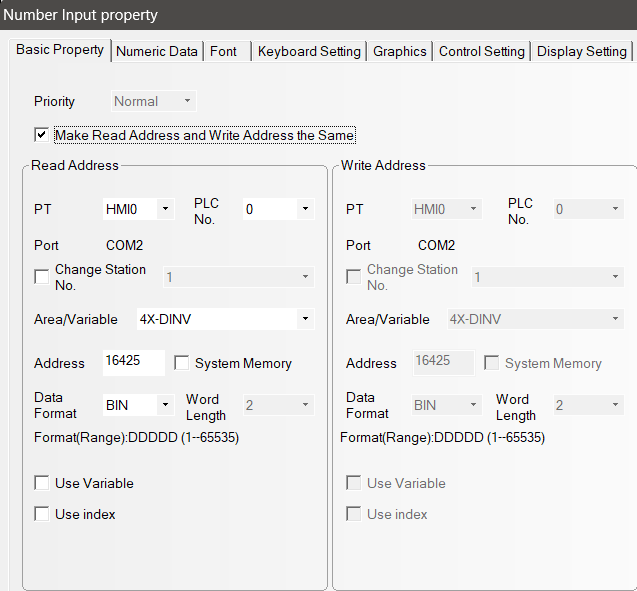

To set speed from HMI, Create a Number Input Property. Set properties as below,

| Property | Value |

|---|---|

| PT | HMI0 |

| PLC NO | 0 |

| Port | COM2 |

| Station | 1 |

| Area | 4X-DINV |

| Address | 16425 |

Change Station Number based on the Node address of the Drive.

Parameter PA2:72

Speed Monitor

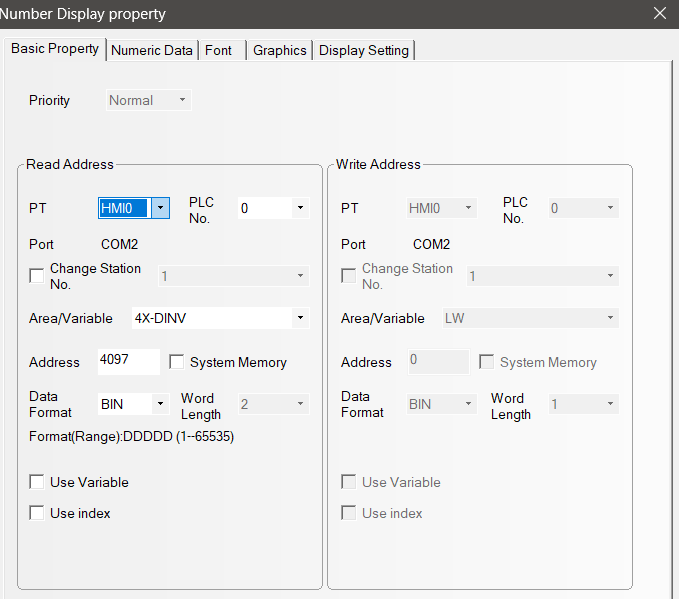

To set speed from HMI, Create a Number Display Property. Set properties as below,

| Property | Value |

|---|---|

| PT | HMI0 |

| PLC NO | 0 |

| Port | COM2 |

| Station | 1 |

| Area | 4X-DINV |

| Address | 4097 |

Please refer to Official Document for more details.